Energy Department Award for Green Parabolic Trough Collector

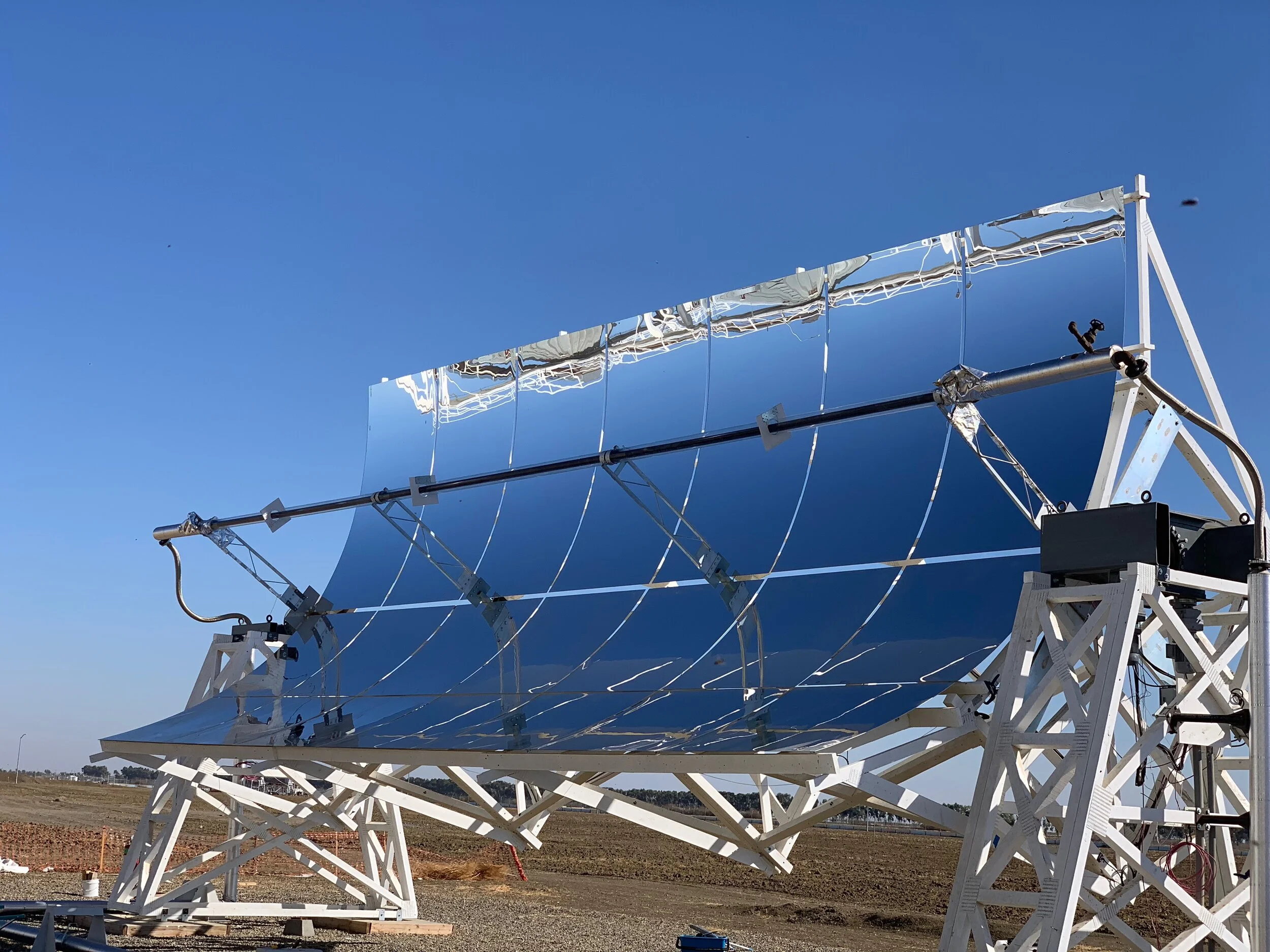

Parity in the levelized cost of solar steam with natural gas requires a breakthrough in the total installed cost of the solar collector. We identified the steel support structure as the highest cost component of the parabolic trough collector, the simplest and most efficient collector for steam generation, and proposed to replace steel with lumber as the structural material as a means of both lowering the cost and significantly reducing the embodied carbon. Steel has been used for over a century for the trough structure. A trough based on a lumber spaceframe opens up a new design space for structural engineering, including the general geometry (“typology”), joint design and characterization, and assembly process to achieve the high level of accuracy needed for 80:1 concentration. With this project we took the significant first step towards demonstrating the feasibility of achieving the low-cost and high performance of a lumber-based design through the systematic development of a full-scale prototype.